VENEER PROCESS

NAVA select the best hard maple logs from North America and Canada and make sure every process is under strict quality control. We will show you how we make a professional skateboard deck in our workshop.

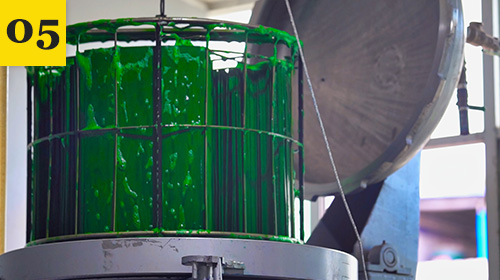

DECK FORMING

In NAVAworkshop, every deck is made with the finest craftsmanship. We have a set of default concave, shape, size, and dye color which is most popular based on our 15 years experience. Besides, we also accept customization of many aspects.

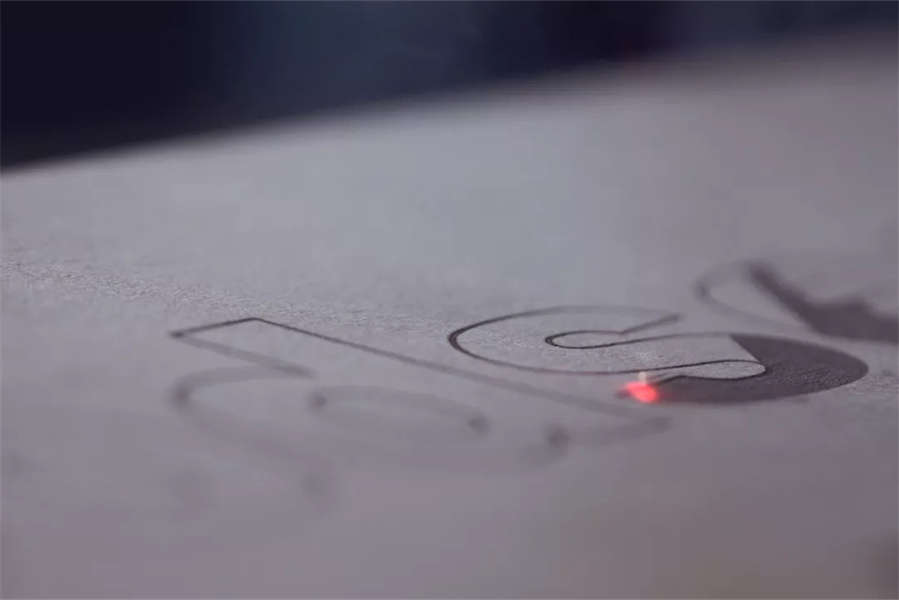

GRAPHIC AND LOGO MAKING

High-precision silkscreen workshop, industrial UV digital printer, Logo Engraving. NAVA could help you to make your design present perfectly in reality